The global pharmaceutical temperature controlled packaging solutions market size was valued at USD 325 million in 2023 and is expected to hit around USD 846.78 million by 2033, growing at a CAGR of 10.10% from 2024 to 2033.

The pharmaceutical temperature-controlled packaging solutions market has witnessed significant growth due to various factors. These specialized packaging solutions are designed to maintain specific temperature ranges required for storing and transporting temperature-sensitive pharmaceutical products such as vaccines, biologics, insulin, and certain medications. With the increasing globalization of pharmaceutical supply chains and the growing demand for biologics and vaccines, there has been a rising need for reliable and efficient temperature-controlled packaging solutions in the pharmaceutical industry. These solutions ensure product integrity and safety by protecting medications from temperature excursions that could compromise their efficacy.

Moreover, advancements in insulation materials, phase change materials, refrigerants, and temperature-monitoring technologies have led to the development of more advanced and reliable temperature-controlled packaging solutions that can maintain precise temperature conditions during transit and storage.

Additionally, the COVID-19 pandemic has further underscored the importance of temperature-controlled packaging solutions as pharmaceutical companies strive to ensure the safe and effective distribution of vaccines and other critical medical supplies. As regulatory requirements become more stringent and the demand for temperature-sensitive pharmaceuticals continues to rise, the pharmaceutical temperature-controlled packaging solutions market is expected to witness sustained growth, offering opportunities for innovation and expansion in packaging technologies and services to meet the evolving needs of the pharmaceutical industry.

Key Takeaways

- In 2023, North America held the largest market share (32.31%) in the world.

- Between 2024 and 2033, the Asia Pacific region is predicted to grow at the fastest rate, 8.2% CAGR.

- In 2023, the pharmaceutical sector that is sensitive to temperature held the greatest market share, accounting for 60.27% of the total.

- In 2023, the product category with the largest revenue share, 65.47%, was reusable.

Get a Sample:https://www.precedenceresearch.com/sample/1163

Pharmaceutical Temperature Controlled Packaging Solutions Market Scope

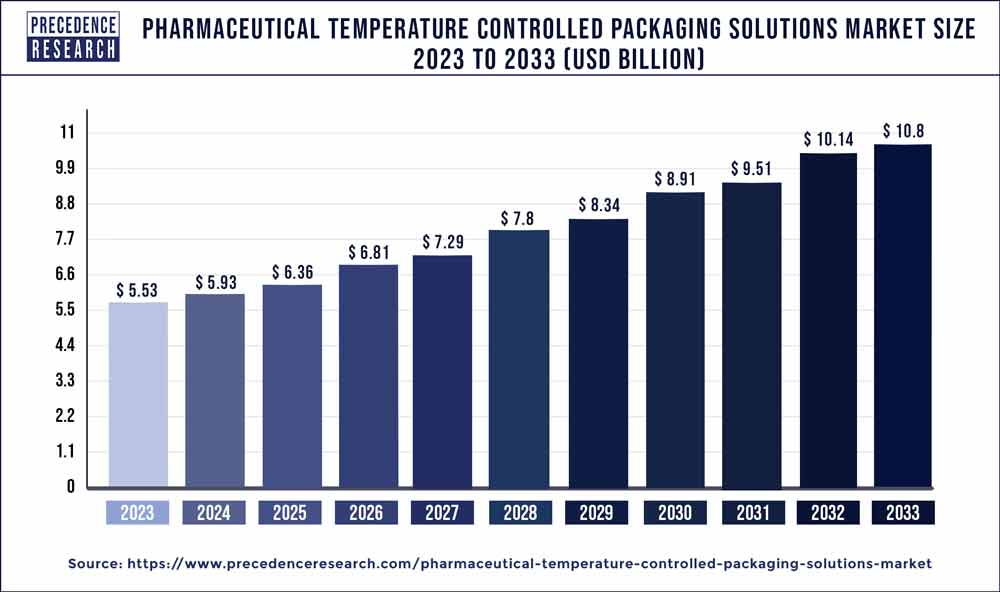

| Report Highlights | Details |

| Growth Rate from 2024 to 2033 | CAGR of 6.9% |

| Market Size in 2023 | USD 5.53 Billion |

| Market Size by 2033 | USD 10.8 Billion |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Product Type, Application Type, Region Type |

Read More: Temperature Controlled Packaging Solutions Market Size to Hit USD 31.25 Billion by 2032

Market Dynamics

Driver

The increasing demand for biopharmaceuticals is driving growth in the pharmaceutical temperature-controlled packaging solutions market. Biopharmaceuticals, which include vaccines, antibodies, proteins, and other biological drugs, are highly sensitive to temperature variations and require strict temperature control throughout the distribution process to maintain their efficacy and stability.

Temperature-controlled packaging solutions play a critical role in ensuring the safe and effective transportation of biopharmaceutical products from manufacturing facilities to healthcare providers and patients. These packaging solutions are designed to maintain specific temperature ranges, such as refrigerated (2°C to 8°C), frozen (-20°C to -80°C), or controlled room temperature (15°C to 25°C), to preserve the integrity and potency of biopharmaceuticals.

One of the key drivers behind the increasing demand for pharmaceutical temperature-controlled packaging solutions is the growing adoption of biopharmaceuticals in the treatment of various medical conditions, including cancer, autoimmune disorders, and infectious diseases. Biopharmaceuticals offer targeted and personalized treatment options with fewer side effects compared to traditional small molecule drugs, driving their popularity among healthcare providers and patients.

Additionally, the globalization of the pharmaceutical supply chain and the expansion of biopharmaceutical manufacturing facilities to emerging markets have increased the need for reliable and efficient temperature-controlled packaging solutions. As biopharmaceutical products are shipped over long distances and stored in various climates, there is a heightened risk of temperature excursions that can compromise product quality and efficacy. Temperature-controlled packaging solutions help mitigate these risks by providing insulation and temperature monitoring capabilities to ensure that biopharmaceutical products remain within the required temperature range during transit.

Restraint

Environmental concerns are significant in the pharmaceutical temperature-controlled packaging solutions market due to the impact of packaging materials, energy consumption, and waste generation on the environment. Temperature-controlled packaging is essential for maintaining the integrity and efficacy of pharmaceutical products, especially those that are sensitive to temperature variations. However, the use of certain packaging materials and refrigeration systems can contribute to environmental degradation and carbon emissions.

One of the primary environmental concerns is the use of non-biodegradable and non-recyclable packaging materials in temperature-controlled packaging solutions. Many traditional packaging materials, such as expanded polystyrene (EPS) foam and plastic films, are derived from fossil fuels and pose challenges for disposal and recycling. Improper disposal of packaging waste can lead to pollution of landfills, waterways, and ecosystems, contributing to environmental harm.

Additionally, the energy consumption associated with temperature-controlled storage and transportation poses environmental challenges. Refrigeration systems, cold storage facilities, and transportation vehicles used to maintain temperature-sensitive pharmaceuticals require significant energy inputs, which often come from non-renewable sources such as fossil fuels. This energy consumption contributes to greenhouse gas emissions, air pollution, and climate change, exacerbating environmental impacts.

Opportunity

Technological advancements are reshaping the pharmaceutical temperature-controlled packaging solutions market, offering innovative solutions to ensure the safe and efficient transportation of temperature-sensitive medications and biologics.

One key advancement is the development of more sophisticated temperature monitoring and control systems. Modern temperature-controlled packaging solutions incorporate advanced sensors and data logging devices that provide real-time monitoring of temperature conditions during transit. These sensors can detect even minor fluctuations in temperature and humidity, allowing for proactive interventions to maintain product integrity and efficacy.

Furthermore, advancements in insulation materials and packaging design have improved the thermal performance of temperature-controlled packaging solutions. Innovative materials with enhanced thermal properties, such as vacuum-insulated panels and phase change materials, help maintain stable temperature conditions inside shipping containers for extended periods. Additionally, optimized packaging designs minimize heat transfer and reduce the risk of temperature excursions during transportation.

Recent Developments

- Phase-change material (PCM) technology developer Pluss Advanced Technologies (PLUSS) announced the launch of two new temperature-controlled packaging options for the pharmaceutical industry in September 2023: the Celsure® XL Pallet Shipper series and the Celsure® VIP Multi-Use Parcel Shipper series.

- The life science industry partner Minneapolis Peli BioThermal, which provides security for deep frozen payloads, expanded its range of reusable Crì“doTM shippers in February 2023. The varied selection of Crì“do CubeTM Dry Ice products will assist in mitigating the current dry ice scarcity, which is adversely impacting the pharmaceutical logistics industry. The new gadgets will assist meet the growing demand for safely delivering temperature-sensitive biologics, as well as time-sensitive cell and gene therapies, to patients.

Pharmaceutical Temperature Controlled Packaging Solutions Market Players

- Pelican Biothermal

- Cryopak

- Sonoco Products Company

- Envirotainer

- DS Smith Pharma

- Cold Chain Technologies

- World Courier

- Intelsius

- CSafe

- Softbox Systems

- Skycell

- Va-Q-tec AG

- Sofrigam

Segments Covered in the Report

By Product

- Reusable Solutions

- Single Use Solutions

By Application

- Temperature-Sensitive Pharmaceuticals

- Vaccines

- Others

By Regional Outlook

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Middle East & Africa

- Latin America

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/1163

Unlocking Market Insights through Data Excellence

The “Precedence Statistics” flexible dashboard is a powerful tool that offers real-time news updates, economic and market forecasts, and customizable reports. It can be configured to support a wide range of analysis styles and strategic planning needs. This tool empowers users to stay informed and make data-driven decisions in various scenarios, making it a valuable asset for businesses and professionals looking to stay ahead in today’s dynamic and data-driven world.

To Access our Premium Real-Time Data Intelligence Tool, Visit:

www.precedencestatistics.com